Below is the available product literature for our ductile iron pipe and corresponding joint types. For more information, please contact a marketing and specifications representative.

-

Pipe Rounding Instructions

This instructional kit takes "out-of-round" out of your construction vocabulary. The instructions are intended and designed to fix this after cutting. With the pipe rounding instructions you can easily change the shape of the pipe, from the outside, during joint assembly.

-

Cost of DI Pipe Tip Sheet

To provide the most accurate and cost-effective pricing for Ductile iron pipe, there are a few items to consider that determine the final cost to the customer. Listed in this tip sheet, but not limited to, are the significant variables that affect DI pipe pricing.

-

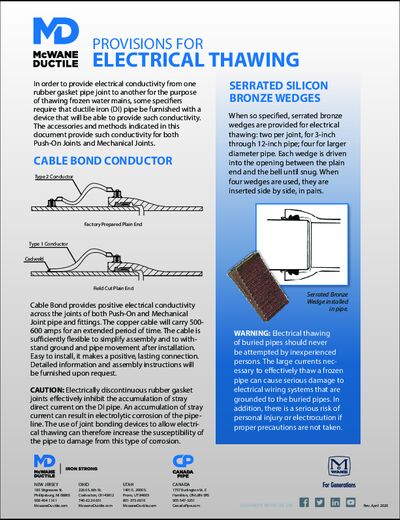

Electrical Thawing Tip Sheet

To conduct electrical current from one rubber gasket pipe joint to another for the purpose of thawing frozen water mains, some specifiers require that Ductile iron (DI) pipe be furnished with devices to provide such conductivity. The accessories and methods for Push-On Joints and Mechanical Joints are listed in this tip sheet.

-

Gasket Storage Tip Sheet

Gaskets are critical components in your Ductile iron piping system. They are made of compound rubber materials that can gradually weather, dry out, and deteriorate if not cared for properly. To avoid damage or deformation, use these guidelines to store your gaskets correctly.

-

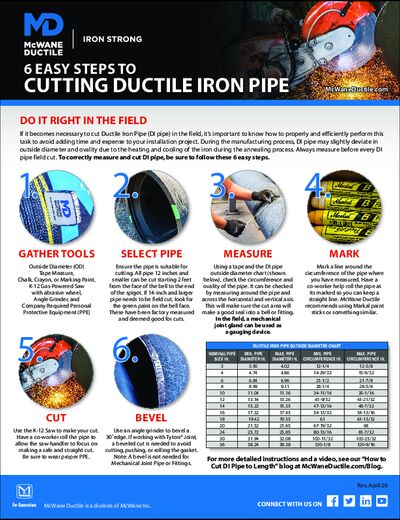

Cutting Ductile Iron Pipe Tip Sheet

If you find it necessary to cut Ductile iron pipe in the field, it is essential to know how to properly and efficiently perform this task to avoid adding time and expense to your installation project. Be sure to follow these 6 easy steps.

-

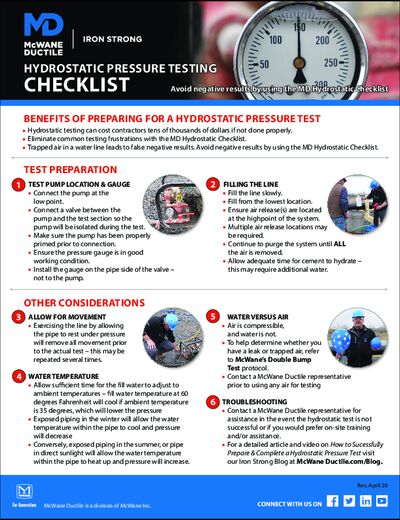

Preparing for a Hydrostatic Pressure Test Tip Sheet

Hydrostatic testing can cost contractors tens of thousands of dollars if not done correctly. Eliminate common testing frustrations and avoid negative results with this helpful checklist.

-

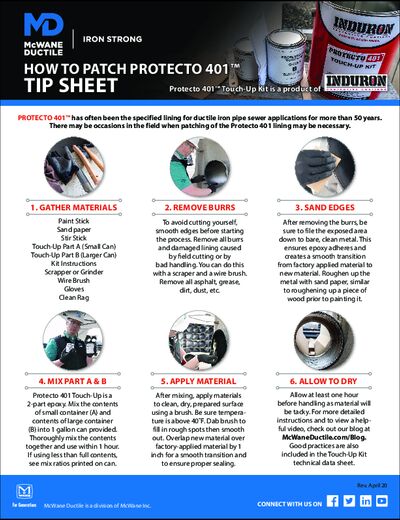

Patching Protecto™ 401 Tip Sheet

There may be occasions in the field when patching of the Protecto 401 lining may be necessary. Use this handy tip sheet to guide you through your repair work.

-

Push-On Joint Assembly Tip Sheet

A displaced or rolled gasket creating water loss in a ductile iron pipeline is one of the most common errors that occur during joint assembly. To avoid displacing or rolling a gasket and to ensure proper joint assembly, be sure to follow these five easy steps.

-

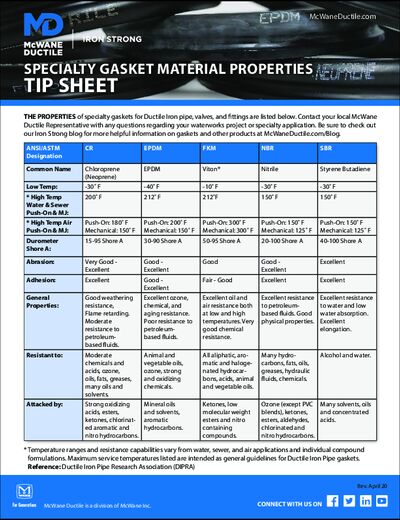

Specialty Gasket Material Properties Tip Sheet

The properties of specialty gaskets for Ductile iron pipe, valves, and fittings are outlined in this handy reference.

-

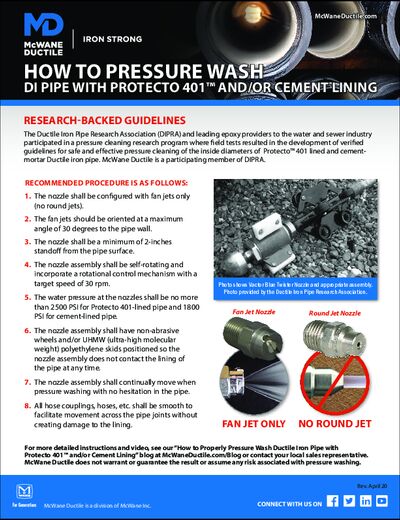

Pressure Washing Protecto™ 401 Tip Sheet

From research and field tests conducted by DIPRA and leading epoxy providers, we have provided verified guidelines for safe and effective pressure cleaning of the inside diameters of Protecto™ 401 lined and cement-mortar Ductile iron pipe

-

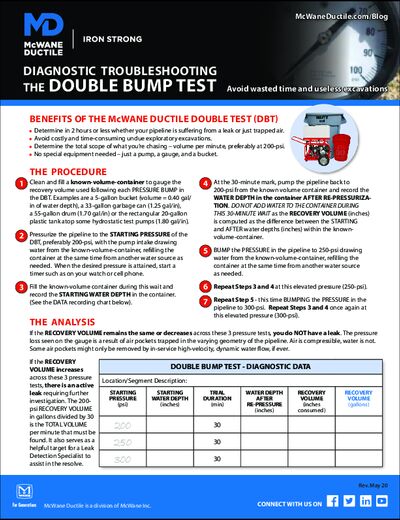

Double Bump Tip Sheet

What do you do when your hydrostatic proof goes POOF? This handy tip sheet will show you how to avoid costly exploratory excavations by determining if a pipeline has a leak or just trapped air.

-

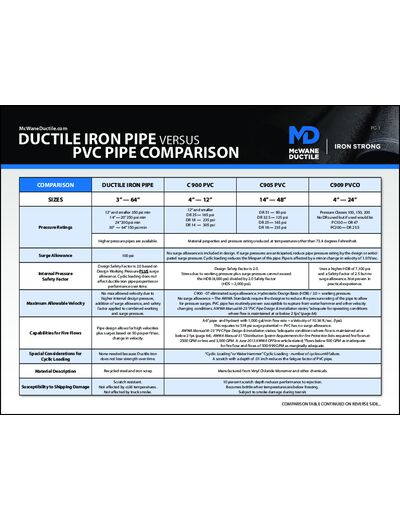

Ductile Iron Vs PVC Pipe Comparison Sheet

What’s the difference between Ductile Iron and Polyvinyl Chloride? Many things! This handy sheet shows the numerous reasons to choose Ductile iron pipe - the safest, longest-lasting pipe for your next water infrastructure project.

-

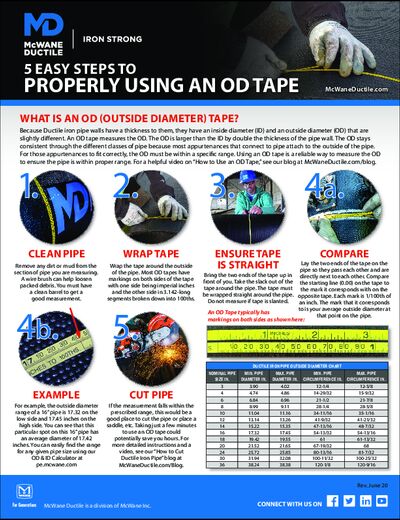

How to Use an OD Tape

Need to measure the Outside Diameter (OD) of Ductile Iron Pipe? Be sure to do it the right way by using an OD Tape! By following these 5 easy steps, you can save valuable time and money on your next DI pipe project.

-

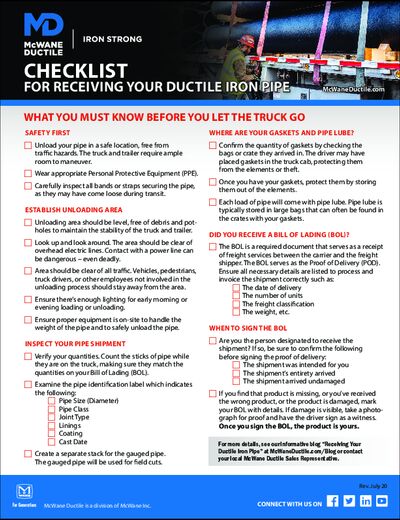

Receiving DI Pipe Checklist

Are you expecting a shipment of Ductile iron pipe? Use this handy checklist that covers what you must know before you let the truck go.

-

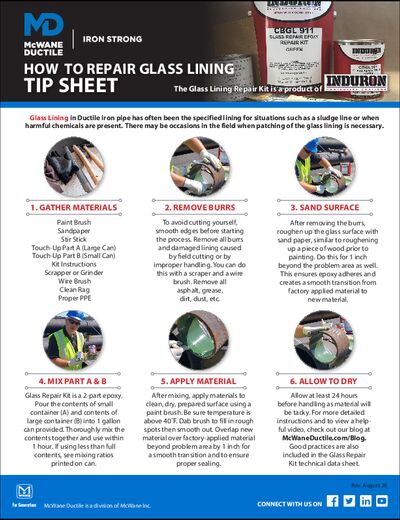

Glass Lining Repair

There may be a time when you must repair the glass lining of your Ductile iron pipe due to a field cut or improper handling. Patch it correctly with this step-by-step tip sheet.