What to do when your hydrostatic PROOF goes POOF? All too often, the tester becomes a prisoner of the gauge, wistfully hoping that somehow, someway, each time the pipeline is pumped back to the same pressure, it would bring a different or better result. On the other hand, in less than 2-hours, the McWane Ductile Double Bump Test (DBT) offers these benefits:

- Determine if the pipeline is suffering from a leak or just trapped air.

- Help avoid costly and time-consuming undue exploratory excavations.

- Establish the full scope of what you are chasing – volume per minute, preferably at 200-psi.

- No special equipment needed – just a pump, a gauge, and a bucket.

Two Ways To Fail

The post-installation hydrostatic proof test (HPT) of a pipeline serves to confirm the pipeline, and all its parts are free from manufacturing deficiency, installation anomaly, or damage during transport and handling. The manufacturing aspect of a pipeline’s fitness is covered in large part by the 500-psi hydrotest of every single pipe at the foundry of origin. The field HPT primarily examines the installation portion of a pipeline’s creation.

There are two simple measures regarding a pass or fail of the hydrostatic proof test;

- Pressure loss greater than 5-psi during the test or

- A recovery water volume that exceeds the computed amount permitted for the diameter and length of the pipeline segment being tested. The allowable recovery volume for any Ductile iron pipeline is easily computed with the Hydrotest Allowance Calculator contained within the McWane Pocket Engineer located at pe.mcwane.com.

Foundation Of The Double Bump Test

Developed over two decades of utility pipeline hydrotesting experiences, the DBT is based on the reliable fact that air is compressible, and water is not. Far too often, a pressure drop is confused for water loss, leading the contractor on a repetitive, frustrating, and costly hunt for what may not be there.

Trapped air is the leading cause of a false-negative result from a field HPT. Time after time – with the pump on, air pockets get compressed, and pressure rises on the gauge.

Turn the pump off, and these pockets expand again, showing a loss on the gauge, often more than 20 or 30-psi depending on pipeline size, length, and geometry.

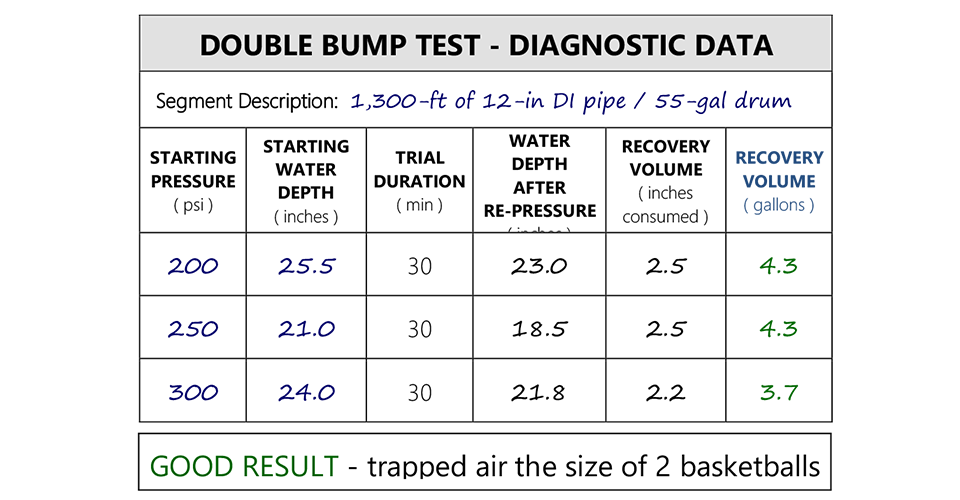

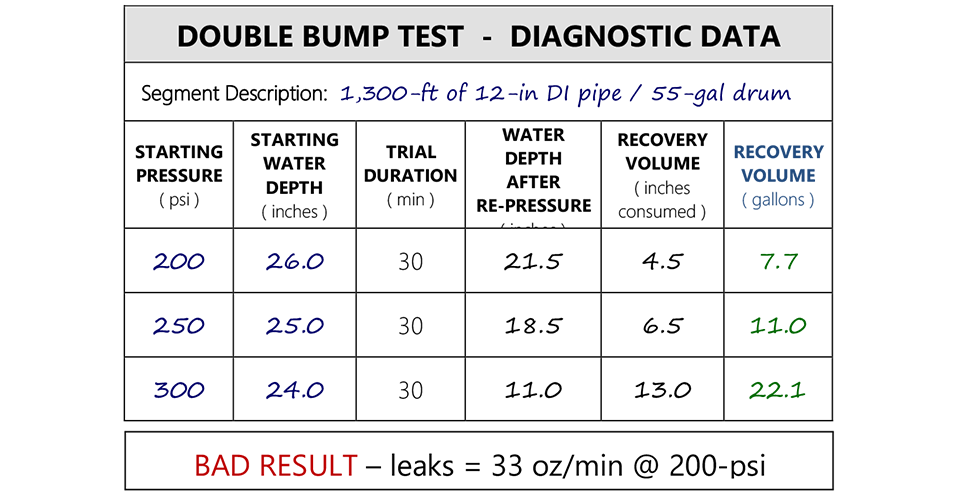

The primary question of “Is this pipeline leaking?” can easily be answered without digging a single exploratory pothole by using the diagnostic procedure known as the Double Bump Test. Simply comparing the recovery volumes across three (3) separate 30-minute pressure tests, bumping the pressure up for each test can ascertain if the pipeline contains trapped air or is losing water.

MUST ASK Questions Before Bumping

When our product engineers receive a call from others informing us that a pipeline is not performing well in the field during a HPT, there are informative questions that must be asked before planning the next best course of action, which typically is the DBT. These questions also serve to PROTECT THE PIPELINE itself from any additional issues being created based upon the original design parameters of the pipeline.

- Is the entire pipeline segment to be tested constructed of Ductile iron pipe?

Significant damage can occur with alternate piping materials if pressures are greater than 200-psi. - How much of what size pipe is involved in the segment being tested?

The length and size of the segment being tested, along with the location of the pump, can affect judgments made from the data collected during the DBT. - What is the highest pressure the pipeline segment of concern has been pumped to?

If the pipeline, for example, cannot be pumped to or above 200-psi, this is an indication of a significant anomaly, such a severely displaced gasket or other significant damage to the pipeline, such as a split, crack, or impact wound through the pipe wall. - Does the pipeline segment being tested fall to 0-psi?

If so, there is a substantial active leak, and the rate of water-loss at 200-psi should be taken as the volume to chase. - Does the pipeline segment being tested fall below any adjacent static pressure but not to 0-psi?

If so, this indicates that the pipeline segment being tested is hydraulically isolated; otherwise, the segment pressure would equalize to the adjacent static pressure. Use the DBT to analyze the next best step to take. - Are there restrained joints in the pipeline segment being tested?

Unrestrained rubber-gasket pipe joints are prone to separate at higher internal pressures. Above ground, with no aid from the weight of backfill, any diameter push-on unrestrained joint can separate from only 50-psi of hydrostatic pressure. - What design pressure was used for the restrained joints in the pipeline section being tested?

It is not recommended to exceed the ultimate design pressure (SF*Pd) established by the engineers for the restrained joints of a pipeline. The Thrust Restraint Calculatorcontained in the McWane Pocket Engineer applies a default safety factor (SF) of 1.5 to the input Design Pressure (psi). Should the user choose to change this Safety Factor to 2.0, the restrained joint requirements (the wiggle zone) would be calculated at twice the input Design Pressure. Using a Safety Factor of 1.0 would compute the restrained joint needs at precisely the input Design Pressure.

Doing The Bump – The Double Bump Test, That Is…

The preferred hydrotest pressures for the Double Bump procedure are 200, 250, and 300-psi, for 30-minutes each. And no worries. Each DI pipe or fitting has been factory tested to a minimum of 500-psi per AWWA standard. Brass/copper service connections to DI pipe, should they be installed prior to testing the pipeline, have been shown through significant DIPRA testing to handle 500-psi easily. AWWA conformant resilient-seat gate valves and/or wedge-action retainer glands perform admirably against 500 psi as well.

The Double Bump Test PROCEDURE is quite simple and very reliable:

- Clean and fill a known-volume-container to gauge the recovery volume used following each PRESSURE BUMP in the DBT. Examples are a 5-gallon bucket (volume = 0.40 gal/in of water depth), a 33-gallon garbage can (25 gal/in), a 55-gallon drum (1.70 gal/in) or the rectangular 20-gallon plastic tank atop some hydrostatic test pumps (1.80 gal/in).

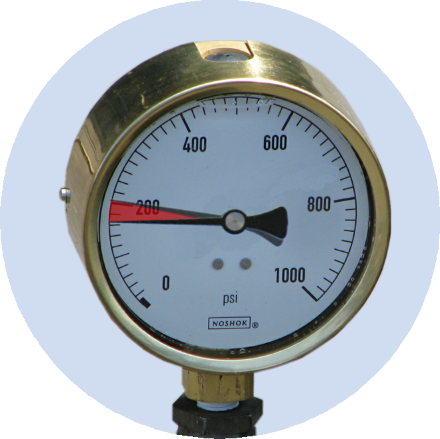

- Pressurize the pipeline to the STARTING PRESSURE of the DBT, preferably 200-psi, with the pump intake drawing water from the known-volume-container, refilling the container at the same time from another water source as needed. When the desired pressure is attained, start a timer such as on your watch or cell phone.

- Fill the known-volume-container during this wait and record the STARTING WATER DEPTH in the container. (See the DATA recording chart below).

- At the 30-minute mark, pump the pipeline back to 200-psi from the known-volume-container and record the WATER DEPTH in the container AFTER RE-PRESSURIZATION. DO NOT ADD WATER TO THE CONTAINER DURING THIS 30-MINUTE WAIT as the RECOVERY VOLUME (inches) is the difference between the STARTING and AFTER water depths (inches) within the known-volume-container.

- BUMP the PRESSURE in the pipeline to 250-psi drawing from the known volume container, refilling the container at the same time from another water source as needed.

- Repeat Steps 3 and 4 at this elevated pressure (250-psi).

- Repeat Step 5 - this time BUMPING the PRESSURE in the pipeline to 300-psi. Repeat Steps 3 and 4 once again at this elevated pressure (300-psi).

ANALYSIS of Double Bump Test Results:

If the RECOVERY VOLUME remains the same or decreases across these three pressure tests, you do NOT have a leak. The pressure loss seen on the gauge is a result of air pockets trapped in the varying geometry of the pipeline. Air is compressible; water is not. Some air pockets might only be removed by in-service high-velocity dynamic water flow, if ever. There is no further investigation needed on this pipeline segment.

If the RECOVERY VOLUME increases across these three pressure tests, there is an active leak requiring further investigation. The 200-psi RECOVERY VOLUME in gallons divided by 30 is the TOTAL VOLUME per minute that must be found. Additional investigation is needed via purposeful excavations or, preferably, chasing the sound with the aid of a leak detection specialist. The best practice is to find all of the leaking 33 ounces/min before effecting any repairs to the pipeline.

Even The BAD Can Be GOOD

Nobody ever wants to experience leaks on a pipeline. However, if or when leaks come your way, it is better to know quickly and precisely what the pipeline is doing instead of wasting valuable time and money with random excavations. The McWane Ductile Double Bump Test truly can make the best of a bad situation, with less frustration from the unknowns, and a swifter overall resolve of the issues.

Now that you have a better understanding of the DBT procedure, be sure to download our handy tip sheets with instructions and a diagnostic data chart by clicking the DOWNLOAD button below.

Need Assistance With Your Waterworks Project?

As always, if you have any questions or require additional information, please feel free to contact your local McWane Ductile representative. We have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.