-

Hydrotesting on Slopes: The Hills Have PSI!

10/28/2021 In Installation TechnicalDear Ditch Doctor: Out here in the western United States, we wind up with a lot of pipelines installed up or down serious hills, dare I say mountains as well? We are good at the construction part, yet time after time we struggle with getting a satisfactory post-installation hydrostatic test on the pipeline, especially with inclined installations. Often the pipeline drops anywhere from 20 to 50 psi on the gauge and can do that several times or more until we take some sort of drastic redo/restart on the test procedures.

-

Barrel Rating vs. Joint Rating for Ductile Iron Pipe: Is There a Difference?

10/15/2021 In TechnicalWhenever the word "rating" is used regarding Ductile iron pipe (DI pipe), a 100-psi surge allowance and a safety factor of 2.0 are consistently included for all wall classes. This leads to conservative yet versatile designs for the long-term performance of utility pipelines of all kinds in various or changing conditions. Hence the basic universal rating for DI pipe is 350-psi which equates to a minimum of 900-psi of hydrostatic pressure containment within the pipeline.

-

What Did I Dig Up - Gray Iron or Ductile Iron Pipe?

06/25/2021 In Products TechnicalSo, the site plans say, "… connect to existing iron pipe." Now that we’ve dug down to it, I can’t tell if it is gray iron or Ductile iron pipe. Are there ways to reliably distinguish between the two without some physical testing on a sample? In this blog, we'll take a closer look at the characteristics and differences between the two types of pipe.

-

Ductile Iron Pipe Weights - An Expanded Explanation

04/16/2021 In Products Services TechnicalThis article takes a deeper dive into concepts outlined in the July 2020 entry prepared by my co-worker Gary Gula, How Much Does Ductile Iron Pipe Weigh and Why Does It Matter to You? Specifically, we will focus on the pipe weight itself, answering questions such as: From where do these weights originate? Why do we show weights on each pipe? How trustworthy are these weights as provided? And, What do these weights mean to me, the pipe customer?

-

Ask the Ditch Doctor - What About Residual Water in Cold Temps?

02/12/2021 In Installation TechnicalDear Ditch Doctor

We recently installed a 15,000-ft 12-inch diameter Ductile iron pipeline with several 6-inch branches off two hydrants. The average depth of cover is 4 feet. The city engineer has expressed a concern that residual groundwater might have entered the pipeline during our installation activities.

-

How Does Proper Bedding Allow a Pipe to “Sleep Well?"

01/22/2021 In Installation TechnicalDid you know the mattress industry is one of the oldest continuous industries in the world? The first mattresses were believed to have been manufactured in 37 BC in Persia. Today, more than 35 million mattresses are shipped world-wide to replace those that have been in service for an average of seven years. So, what does this have to do with Ductile iron pipe (DI pipe), you ask? This article will discuss how setting improper bedding in a pipe trench can cause sleepless nights for the water company and its crews due to pipe failures, seemingly always at night — as it is my experience that most large main breaks typically occur after dark!

-

Cyclic Pressures - What's the Difference Between Ductile Iron & PVC and How Do I Accommodate In Pipe Design?

07/25/2020 In Products TechnicalThis entry in the Iron Strong Blog compares the performance of Ductile iron pipe (DI pipe) to Polyvinyl Chloride (PVC) pipe against cyclic pressure variations in piping systems. Cyclic loading, or more accurately, cyclic surges, is a phenomenon where pressures in a pipeline frequently vary due to changes in demand, operating conditions, storage tank levels, treatment plants, and pump starts and shutdowns. Surges can also occur during common field operations such as exercising or flushing fire hydrants or valves within the system, which can drastically change flow parameters, causing surges or water hammers.

-

How To Perform The Double Bump Test – A Diagnostic Procedure From McWane Ductile

05/15/2020 In TechnicalWhat to do when your hydrostatic PROOF goes POOF? All too often, the tester becomes a prisoner of the gauge, wistfully hoping that somehow, someway, each time the pipeline is pumped back to the same pressure, it would bring a different or better result. On the other hand, in less than 2-hours, the McWane Ductile Double Bump Test (DBT) offers these benefits:

-

HDPE and DI Pipe - Differences That Matter - A Comparative Narrative

11/22/2019 In Installation TechnicalWhen choosing an appropriate utility piping material for your water or wastewater project, there is so much more to consider than just the purchase price alone. This comparison between two popular piping materials – HDPE and Ductile iron pipe – demonstrates the need for more than just a cursory review or habitual choice. At McWane Ductile, we are always available to run through the matrix with you. Some installations or conditions do favor alternate materials, yet it’s hardly ever a cut-and-dried deal. Let’s take a closer look to find out why.

-

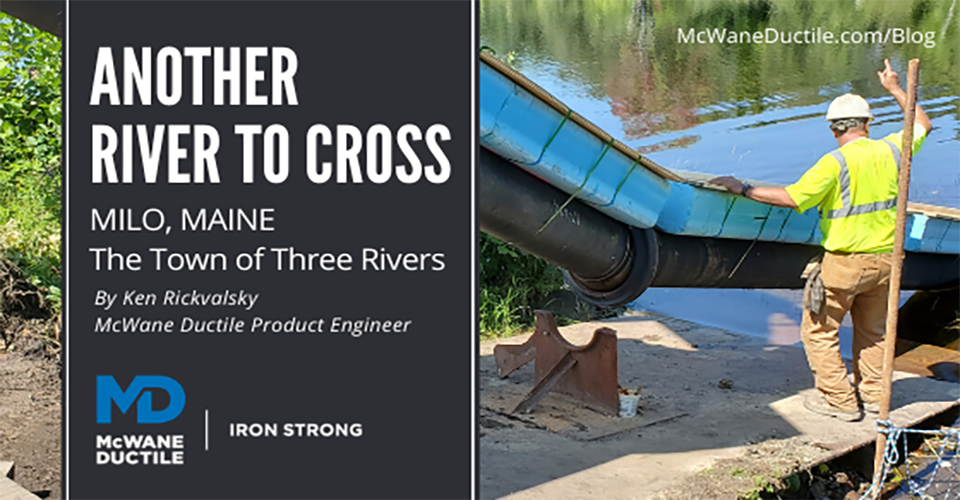

Another River to Cross: Milo, Maine, The Town of Three Rivers

11/07/2019 In InstallationForty miles north of Bangor, Maine, at the confluence of the Piscataquis, Pleasant and Sebec Rivers, is the town of Milo Maine, a charming enclave founded in 1802. The early history of Milo was dominated by iron works and railroads where it soon became home to the second largest railroad car and repair facility in the New England territory at that time.

Latest Posts

- The Iowa Treated Water Pipeline Project: Providing Growth with Safe, Clean Water 11/09/2021 In Installation Services

- Hydrotesting on Slopes: The Hills Have PSI! 10/28/2021 In Installation Technical

- Barrel Rating vs. Joint Rating for Ductile Iron Pipe: Is There a Difference? 10/15/2021 In Technical

- Corrosion Control - Inside and Out - for Ductile Iron Pipe 10/08/2021 In Products Technical