What do I do with an out-of-round piece of ductile iron pipe?

Is every piece of ductile iron pipe round? The short answer is no, but most of the time it is so slight that it is not even noticeable to the user. In fact, the way pipe is manufactured today, out-of-round issues are rarely a concern. At our foundries, there are quality assurance procedures in place that help safeguard this from occurring. However, there are still occasions when a pipe may be encountered in the field, typically on a field cut, that it is just too oval to facilitate an easy assembly.

So, what do I do if it’s not “round”?

Before we get into the nuts and bolts of things, let’s talk about ovality. In the pipe world, ovality is defined as “a deviation from the circular nominal cross section”. Pipe made of any material can be become oval, or out-of-round. This can occur due to various factors from the manufacture of the pipe to shipment and handling of it upon receipt. Because ductile iron pipe is designed as a flexible conduit, there is a chance it can become oval.

Being out-of-round, or sometimes referred to as “egg shaped”, does not make the pipe bad, but it does give you the opportunity to use our rounding kit. The kit won’t magically shrink or grow your pipe, but it can help make it round again. Once the ovality is adjusted the pipe can easily be installed in the bell of another pipe, valve or fitting.

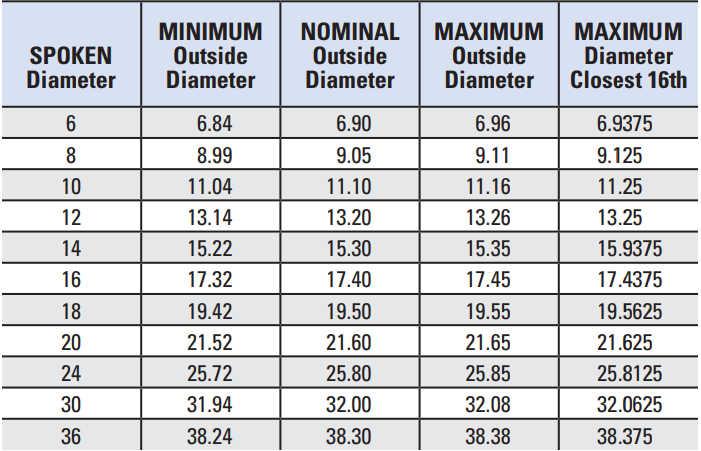

Pro Tip: If you saw our earlier blog about measuring your pipe before you cut, then you will know that it is important to do so. Having a “green bell”, or gauged pipe, does not mean it will always be round. Pipe may also “spring” out of round when you cut it, but that it is within AWWA standards for the minimum and maximum OD’s set by the standard.

How to use the rounding kit:

As you can see our kit is an external one. There are other rounding kits available out there in the ductile world but most are an internal jacking system and require someone to be on the inside of the pipe. Our external kit for McWane Ductile Pipe eliminates that need.

Step by Step: How to Use Field Rounding Kit

1. Measure your pipe where you plan on cutting it. Make sure that area falls within the AWWA acceptable standards range.

2. Cut pipe. Be sure to use a carbide abrasive or diamond tipped blade to make a smooth even cut.

3. Be sure to bevel edge if using on a push joint assembly.

4. Check to see if pipe is still round. Hint: a good way to check this is to use a mechanical joint gland that can be used as a field ring to check the roundness of the pipe.

5. If the gland fits over the plain end you can proceed with normal assembly. If it does not, then it’s time for you to break out the kit and move on to step 6.

6. You will want to set the long axis of the pipe in a vertical or near vertical position. This makes the placing of the jack much easier. The objective is to transform the long and short axes of pipe to get back to being equal to insert in a fitting, valve or pipe bell.

7. Set the jack at the high point of the pipe and wrap the chain around the pipe in mild tension. You want to be close enough to the affected area but also far enough away to allow the measuring gland easy access onto the pipe while giving the finished joints insertion potential.

8. Now let’s get rounding. The best position to do this is behind the jack. It makes assembly observation much easier. Remember to leave the jack in place until final assembly of the joint. Make sure the joint is properly lubricated as well.

9. Once the joint has been assembled and Tee Head bolts have been tightened, you can release the tension on the chain. Then you can then remove the kit from the pipe and continue with the tightening of all bolts including the restraint bolts on the retainer gland. The pipe will relax once the kit is removed, but the joint will still function as intended.

Pro Tip: Each joint of pipe needs to be addressed differently. The purpose of the kit is to turn that oval back to a circle. Some pipe requires very little, others a bit more. The size of the pipe, the wall thickness and the severity of the ovality will all play a part in what needs to be done.

One thing is for sure: DO NOT USE EXCESSIVE FORCE OR EXTENDED MEANS TO CREATE UNSAFE LEVERAGE OR STRAIN UPON THE JACK OR CHAIN.

Just for a little peace of mind, ovality is not a common occurrence, you can lay thousands of feet of large diameter ductile and never once have to use this kit. But when it does happen, you now know one of the most convenient ways to make your pipe round and ready to use. It’s a simple procedure and it works very well on all our McWane Ductile larger diameter pipe when needed. Best of all you don’t have to go crawling inside a piece of pipe.

Kits are available from your local distributor or McWane Ductile Sales Representative. Make sure to visit our Sales Rep page to find the best representative to serve your needs in your area.