What is Tuberculation and why was it happening in Iron Pipe?

Gray cast iron pipe was originally sold with no lining or coating on the interior of the pipe. After many years of study, it became apparent that the inside of cast iron pipe might be affected by certain types of water. So, starting around 1860, most grey iron pipe was sold with a hot-dip bituminous coating.

Hot-Dip Coating

After years of providing this hot-dip coating, it was discovered that where soft or acidic waters were in existence, problems occurred - such as the water turning red or rusty in color as well as a gradual reduction in flow area through the pipe. Basically, aggressive water penetrated the pinholes in the bituminous inner surface and internal corrosion in the form of tuberculation occurred.

This led the iron pipe industry to realize that there was a need for a better protective mechanism to combat tuberculation and thus research and experiments began with cement-mortar as the lining material of choice. Tuberculation is a bacterial-based oxygen-driven form of corrosion that results in iron oxide precipitation. In other words, the deposition of ferrous oxide (tubercles) from the water, as opposed to material being “taken way,” which is how corrosion is normally perceived and resulted.

Cement-Mortar Lining

In 1922, the first cement-mortar lined gray iron pipe was installed in Charleston, SC. Frictional flow tests conducted on this pipe as recent as 1999 revealed that this original cement-mortar lined gray iron pipe has retained a Hazen-Williams coefficient (or “C” value) of 130.

Since 1922, there have been many improvements in the production of cement-mortar lined iron pipe. Cement-mortar lined pipes are centrifugally lined at the plant to ensure the best possible quality control is maintained and that a uniform thickness of mortar is fully distributed throughout the entire length of the pipe. Cement-mortar linings are also smooth, which generates the resulting high flow coefficient numbers.

Modern innovations in the cement-lining and high-speed rotational wring-out process for ductile iron pipe have made the standard “design value C of 140” a functionally conservative number. Numerous flow tests on pipelines installed in the past 20 years have demonstrated in-service performance C values of 150 and higher.

How Does Cement-Mortar Lining Solve This Problem?

Cement-mortar linings prevent tuberculation by creating a high alkaline environment (pH) at the cement/iron pipe wall interface in conjunction with providing a physical barrier to the water. The water will not be in physical contact with the iron pipe wall, and therefore the possibility of any iron-oxide reaction is eliminated. Cement-mortar linings are also smooth, which generates the resulting high flow coefficient numbers.

Ductile iron pipe installed in water systems today is furnished with a cement-mortar lining unless otherwise specified by the owner. To be quite honest, it has been several years since typical Ductile iron pipe specifications have not required cement-mortar lining. BOTTOM LINE IS: if using cement-mortar lined ductile iron pipe in your system, tuberculation will not be an issue. Minor exceptions in the cement lining of a pipe or fitting, such as spalling at a cut end, have not ever shown to promote or permit tuberculation of any measure.

Myth Busted

If you are being told by someone that you should be concerned with tuberculation in your cement-mortar lined ductile iron pipe water system, please have them contact us so we can alleviate their concerns. All too often our industry has seen alternate (substitute) piping materials raising “the tuberculation issue” with photographs that are disingenuous at best, in that they feature older unlined/bare metal flow surfaces without being stated as such.

Utilities or municipalities who have concerns that their water may be aggressive to cement-mortar linings without seal-coat are encouraged to follow the procedure detailed in Section II.A, “Use of Seal-Coat,” in the Foreword to the ANSI/AWWA C104/A21.4 Standard to determine if a cement-mortar lining, without seal-coat, will impart objectionable hardness or alkalinity to the water.

Our industry is not aware of any potable water distribution system in the United States where standard cement-mortar lined Ductile iron pipe is not applicable. Cement-mortar lined Ductile iron pipe is generally considered to be suitable for continuous use at pH between 4 and 12 for seal-coated linings, and between 6 and 12 for non-seal coated linings. For service with pH outside this range, please contact a member company or DIPRA.

A pipe lining must provide a high Hazen-Williams flow coefficient “C” initially and must have enough durability to maintain a high flow coefficient over many years of service. Numerous flow tests have been made on operating pipelines throughout the United States to determine how well cement-mortar linings meet these basic requirements. Tests on both new and old water mains have established the average value of “C” that can be expected of new cement-mortar lined iron pipe and have also provided a measure of the continued effectiveness of such linings over extended periods of service.

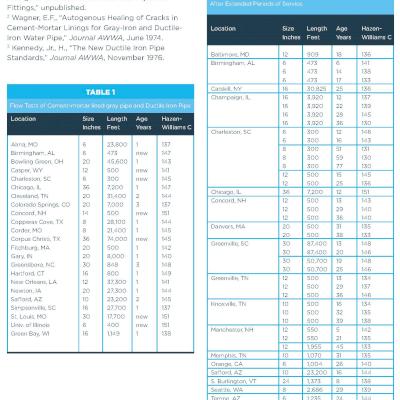

Table 1 presents the results obtained from several friction flow tests made on new, or relatively new, cement-mortar lined iron pipe. The average value of “C” for new pipe of 4-inch through 36-inch diameter was found to be 144.

Table 2 presents the results obtained from numerous friction flow tests made on cement-mortar lined gray iron pipe and ductile iron pipe installed anywhere from 5 years to 77 years ago. Even the oldest pipes carrying the most aggressive waters continue to exhibit “C” values in the same range as the new cement-mortar lined pipe.

Do you have more questions or concerns?

If you have questions or concerns regarding tuberculation in your ductile iron pipe water systems, or any questions regarding the “C” factor for ductile iron pipe, please contact your local McWane Ductile representative. We will be more than happy to visit and discuss this with you. We also recommend that you visit www.Dipra.org and read their paper on “Cement-Mortar Linings for Ductile Iron Pipe”.

Be sure to check out all our digital offerings: