Over the past several years, you may have heard a lot about applying zinc to your Ductile iron pipe (DI pipe) as either a means of corrosion protection or as an added product which will extend the life of DI pipe in a non-corrosive environment.In this blog, we will look a bit closer at the origin of the practice and effectiveness of using zinc for external corrosion protection.

Why is Zinc not recommended as a stand-alone system?

Zinc has been used as a method of external corrosion control for DI pipe in Europe for over 60 years, largely without polyethylene encasement. However, time and again the amount of zinc that must be applied increases with each revision of the standard. Remember, zinc is a sacrificial material and as such it is not recommended as a stand-alone corrosion protection system.

If you are specifying zinc in a corrosive environment, without the additional protection of polyethylene encasement the pipe will begin to show signs of corrosion once the zinc has been consumed. You could expect to see a short increase in service life of the pipe, but the cost effectiveness would be questionable.

Does zinc coated DI pipe add to the life expectancy of your pipeline?

In a non-corrosive environment, DI pipe has been demonstrated to have a standard life expectancy of well over 100 years. This is documented by the The Ductile Iron Pipe Research Association which recognizes over 500 utilities as members of the “Century Club”, meaning they have had iron pipe lines in continuous service for over 100 years. Many of these documented pipe lines are still in service today.

It is McWane Ductile’s position that there is not enough empirical data available at this time to conclude that applying zinc to the surface of DI pipe will result in a specific added life when the pipe is installed in a non-corrosive environment.

When should you specify zinc coated DI pipe?

Did you know that the vast majority of domestic soils are deemed non-corrosive? In these environments, there is no need for zinc, special coatings or poly-wrap. However, despite this finding, the request for zinc coated pipe has become more prevalent. Let’s look at the two possible reasons for specifying zinc coating.

First, an engineer or utility may think that specifying zinc coating in what would typically be a non-corrosive environment is worth the added cost “as an insurance factor” – much like adding wall thickness by requiring a heavier class of pipe. In this case, you can expect the added zinc on the pipe will cost 15 to 20 percent or more in some cases. But remember, standard seal coat “shop coating” on the pipe is provided at no additional cost, and really all that is needed in most non-corrosive environments!

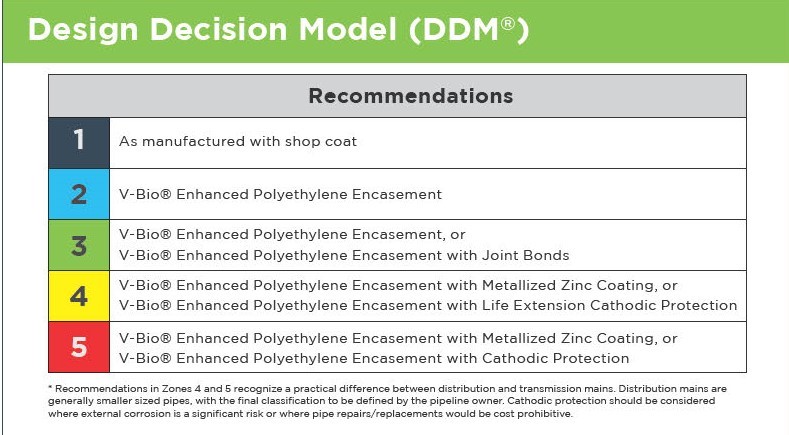

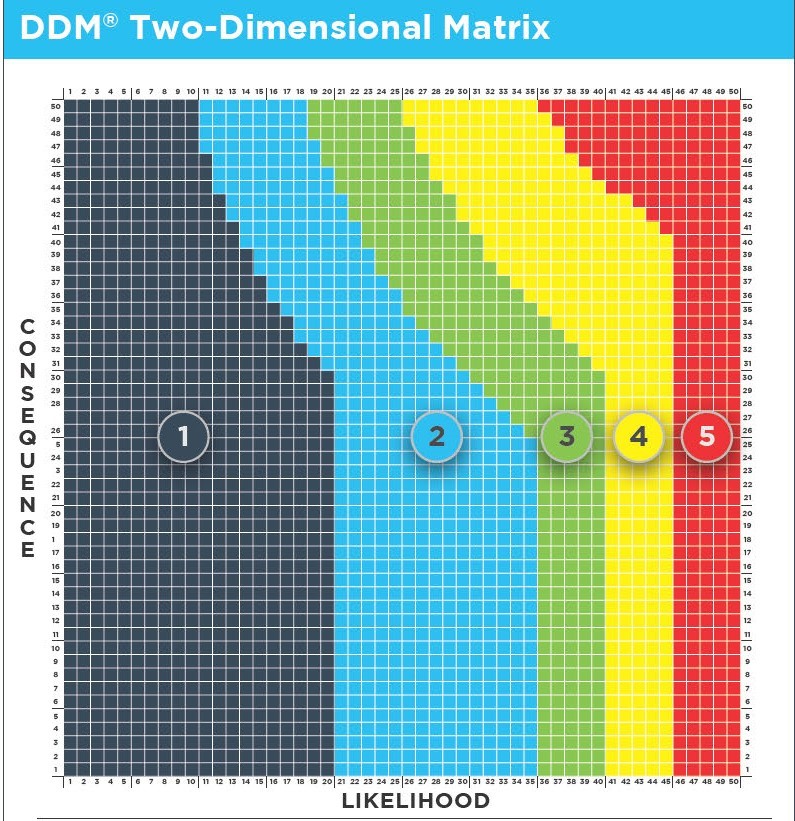

Second and more importantly, if your project falls in either Zones 4 or 5 of the Design Decision Model, or DDM, it is recommended that you specify V-Bio® Enhanced Polyethylene Encasement along with the Metalized Zinc Coating, or V-Bio® Enhanced Polyethylene Encasement along with Cathodic Protection in some extreme circumstances.

What is the Design Decision Model (DDM)?

The DDM, established through a joint effort between the Ductile Iron Research Association and CORRPRO®, utilizes a two-dimensional risk-based model for corrosion control of DI pipe. The DDM plots recommendations for corrosion control based on the likelihood of corrosion and the consequences of a failure. Once plotted, these two variables will yield a recommended level of protection for your DI pipe. These recommendations range from Zone 1 and the use of “as manufactured with shop coat” to the above referenced Zones 4 and 5 recommendations.

What is typically recommended as corrosion protection for DI pipe?

For decades, utilities have utilized polyethylene encasement to address their corrosion concerns. Polyethylene encasement remains the most effective and economical solution.

The American Water Works Association released a report, "Buried No Longer: Confronting Amrica's Water Infrastructure Challenge" (AWWA, 2012) that shows the service life of DI pipe in a corrosive environment can still exceed 105 years when utilizing "evolved laying practices" such as polyethylene encasement. This exceeds the life expectancy of any alternative pipe material on the market today, corrosive environment or not.

Takeaways

After reading this article, I hope that you take away a few key points:

- Zinc coatings are not recommended as stand-alone corrosion protection.

- Zinc could add service life to your DI pipe, but there is not enough quantifiable data to establish how much extended life would be achieved.

- The DDM only recommends the use of zinc and polyethylene encasement in the most extreme conditions (Zones 4 and 5).

- Polyethylene encasement remains the most recommended and economical means of corrosion protection for DI pipe

Please contact McWane Ductile and one of our NACE Certified Corrosion Technicians who would be happy to assist with the evaluation of your job site conditions to ensure that you specify the appropriate method of corrosion protection for your project.

Want tips and instruction to help your team succeed in the field?

To request a Lunch & Learn, a Day of Water, or on-site training with our team of water professionals, contact us before installing your next ductile iron pipeline. McWane Ductile provides free training and education to suit your needs.

Check out all our digital offerings: