-

What Are Common Installation Methods for Ball & Socket River Crossing Pipe and How is it Assembled?

05/14/2021 In Installation ProductsAs the name suggests, Ball & Socket River Crossing Pipe manufactured by McWane Ductile is a severe application Ductile iron pipe (DI pipe) product manufactured to meet the demanding requirements associated with crossing rivers, streams, and lakes. In this blog, we will discuss the various installation methods associated with Ball & Socket pipe and basic assembly instructions.

-

What is the Maximum Direct Tap Size for Ductile Iron Pipe?

09/10/2020 In Installation TechnicalWith Ductile iron pipe (DI pipe), typical service taps can be installed directly into the wall of the pipe, which is called “direct tapping.” The ability to use direct tapping eliminates the need for tapping saddles. And the ease at which DI pipe can be "hot tapped" helps avoid the issue of unhappy consumers because their service and pressure are not impacted by the addition of a new tap. The waterworks community frequently asks us, “How big of a tap will DI pipe allow?” The simple, most conservative response, not having interrogated the user as to their DI pipeline particulars, would be as follows:

-

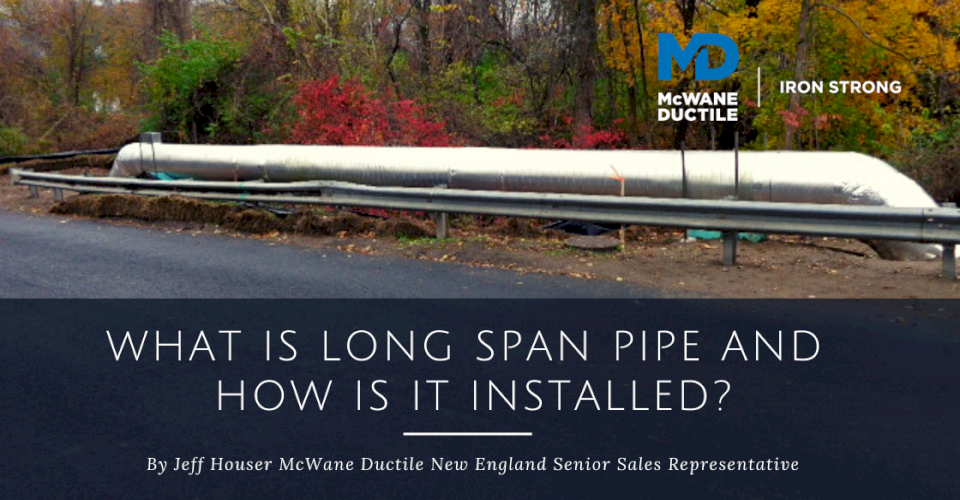

What is Long Span Pipe and How Is It Installed?

05/21/2020 In Installation ProductsAs the name suggests, Long-Span pipe can extend over distances with fewer supports than conventional Ductile iron pipe (DI pipe). In standard 18-foot lengths of DI pipe, a minimum of one support is required within 2-feet of the Bell for each length of pipe. When using Long-Span pipe, distances of 27-foot up to 45-foot and longer can be achieved with support only at the Bell ends.

-

What to Do When the Cement Lining in Ductile Iron Pipe is Damaged

08/08/2018 In Products TechnicalCement-mortar lining for iron pipe has been used for nearly 100 years. The first installation of gray iron pipe with a cement lining was recorded in Savannah, GA in 1922. Todays modern Ductile iron pipe still utilizes cement lining for a safe and reliable means of providing clean drinking water to millions of people every day.

On occasion, however, the cement lining may have incurred some damage in the field. The lining, although very durable, does not have the same resistance to bending stress or impact as the pipe itself. Certainly, the pipe or fitting should be checked for further structural damage, but once determined the affected area is only the cement lining, repairs can be made under the applicable provisions within the ANSI/AWWA C104/A21.4 standard CEMENT-MORTAR LINING FOR DUCTILE IRON PIPE AND FITTINGS.

-

Ductile Iron Pipe Markings: What Do They Mean?

07/24/2018 In ProductsAll ductile iron pipe manufacturers use markings in a similar manner to assist customers in selecting the right material for the project. This includes verifying the material is suitable for the application intended (i.e. water or sewer) as well as adhering to the project requirements as stipulated by the owner/engineer for pipe class, lining, and exterior coating.

Because the colors used by each manufacturer may vary, we will explain how McWane Ductile applies these markings and describe their need and locations.

Latest Posts

- The Iowa Treated Water Pipeline Project: Providing Growth with Safe, Clean Water 11/09/2021 In Installation Services

- Hydrotesting on Slopes: The Hills Have PSI! 10/28/2021 In Installation Technical

- Barrel Rating vs. Joint Rating for Ductile Iron Pipe: Is There a Difference? 10/15/2021 In Technical

- Corrosion Control - Inside and Out - for Ductile Iron Pipe 10/08/2021 In Products Technical