-

Ask the Ditch Doctor - What About Residual Water in Cold Temps?

02/12/2021 In Installation TechnicalDear Ditch Doctor

We recently installed a 15,000-ft 12-inch diameter Ductile iron pipeline with several 6-inch branches off two hydrants. The average depth of cover is 4 feet. The city engineer has expressed a concern that residual groundwater might have entered the pipeline during our installation activities.

-

Can Ductile Iron Pipe Be Ordered in Shorter Bell and Spigot Lengths?

01/29/2021 In Installation Products TechnicalHave you ever wondered or asked if it is possible to order shorter lengths of bell and spigot Ductile iron pipe (DI pipe) for your waterworks project or sections within it? The answer is YES; we can help you with those shorter lengths of DI pipe for your project.

-

How Does Proper Bedding Allow a Pipe to “Sleep Well?"

01/22/2021 In Installation TechnicalDid you know the mattress industry is one of the oldest continuous industries in the world? The first mattresses were believed to have been manufactured in 37 BC in Persia. Today, more than 35 million mattresses are shipped world-wide to replace those that have been in service for an average of seven years. So, what does this have to do with Ductile iron pipe (DI pipe), you ask? This article will discuss how setting improper bedding in a pipe trench can cause sleepless nights for the water company and its crews due to pipe failures, seemingly always at night — as it is my experience that most large main breaks typically occur after dark!

-

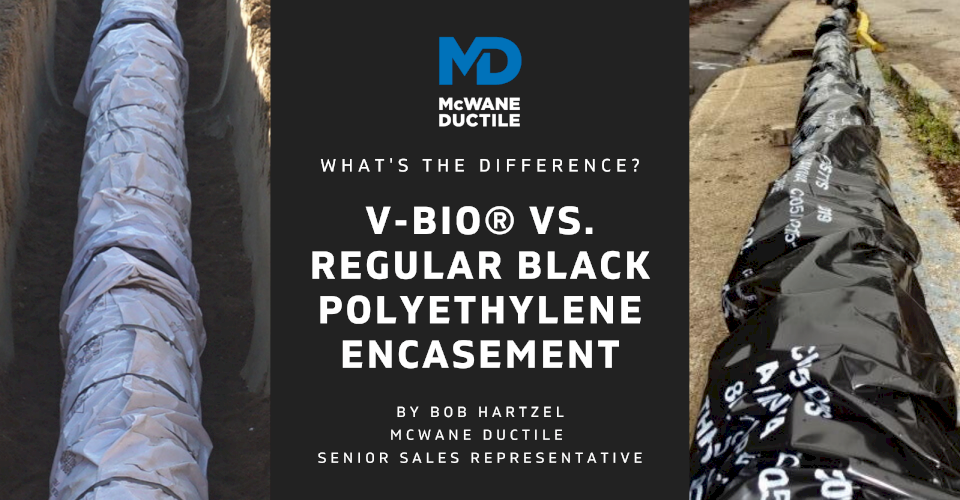

V-Bio® Vs. Regular Black Polyethylene Encasement – What’s The Difference?

12/30/2020 In Installation TechnicalPolyethylene Encasement (Polywrap) was first used in 1958 and has successfully protected millions of feet of both cast and Ductile iron pipe (DI pipe). It has been the most popular method of corrosion control for DI pipe throughout the years. Today, it is the most widely used method of protecting DI pipe in corrosive environments.

-

What Is No Bell Pipe and What Is It Used For?

12/10/2020 In Installation Products TechnicalWhy do you make Ductile iron pipe with no bell? Who would use such pipe? What is it used for? All good questions from most people in our industry, unless you are a pipe fabricator.

-

Why Should I Use Pipe Lubricant Supplied by the Pipe Manufacturer?

11/20/2020 In Installation ProductsFirst, let us establish that all Ductile iron pipe, whether using push-on joints such as Tyton Joint® and TR Flex® Restrained Joints or Mechanical Joint pipe requires the gasket to be properly lubricated prior to joint assembly. Secondly, there is no such thing as too much lube when appropriately applied, especially when using McWane Sure Stop Restraining Gaskets. In this Iron Strong Blog, we will focus on why it is recommended to use the lubricant supplied by the pipe manufacturer.

-

CUSTOMER SPOTLIGHT: Piecing it Together with Peace River

11/13/2020 In Installation Our Company ProductsPeace River Manasota Regional Water Supply Authority has been in operation since 1991 and provides drinking water to more than 900,000 people throughout Charlotte, Desoto, Manatee, and Sarasota Counties in Florida. The Integrated Loop System Phase 1 Interconnect Project was bid in late 2018 and began in early 2019.

-

Ask The Ditch Doctor - Seeing Eye to Eye with The Inspector's Camera

11/06/2020 In Installation TechnicalDear Ditch Doctor,

The county engineer is requesting that we dig up and replace sections of a newly installed Ductile iron pipeline as a result of comments or notations made by an internal video inspection camera operator. I've looked over the “issues” he's noted and can't for the life of me make out what he's talking about.

-

How to Design the Thickness of Ductile Iron Pipe in One Click

10/23/2020 In Installation TechnicalEngineers are busy. They are faced with making critical calculations every day, especially regarding water and wastewater infrastructure. In this article, we will discuss five ways to design the thickness of Ductile iron pipe (DI pipe). Three of them are extremely quick and easy, the other two…maybe not so much

-

How Do I Ensure I Have the Proper Size Casing Pipe for My Ductile Iron Carrier Pipe & What Else Might I Need to Know?

10/16/2020 In Installation TechnicalMost people commonly think the answer to this question is relatively simple. “All I need to do is make sure the Inside Diameter of the casing pipe is larger than the outside diameter of my carrier pipe.” While that is a correct answer, it isn’t necessarily the best answer. Within this Iron Strong Blog, we will closely examine what you need to consider when selecting a casing pipe to fit your application.

Latest Posts

- The Iowa Treated Water Pipeline Project: Providing Growth with Safe, Clean Water 11/09/2021 In Installation Services

- Hydrotesting on Slopes: The Hills Have PSI! 10/28/2021 In Installation Technical

- Barrel Rating vs. Joint Rating for Ductile Iron Pipe: Is There a Difference? 10/15/2021 In Technical

- Corrosion Control - Inside and Out - for Ductile Iron Pipe 10/08/2021 In Products Technical