-

What Are Mill Certs and Why Are They Needed?

08/23/2018 In Our CompanyAccountability through traceability. That’s the cornerstone of Quality Assurance in any manufacturing process.

Often referred to by the abbreviation QA, if you don’t have firm control of this, you don’t have a product worth using. Quality products where lifetime warranties and reliability begin.

McWane Ductile is dedicated to continuous improvements in both product quality and personnel safety throughout all aspects of the process, in our foundry as well as the end-users’ systems.

-

What to Do When the Cement Lining in Ductile Iron Pipe is Damaged

08/08/2018 In Products TechnicalCement-mortar lining for iron pipe has been used for nearly 100 years. The first installation of gray iron pipe with a cement lining was recorded in Savannah, GA in 1922. Todays modern Ductile iron pipe still utilizes cement lining for a safe and reliable means of providing clean drinking water to millions of people every day.

On occasion, however, the cement lining may have incurred some damage in the field. The lining, although very durable, does not have the same resistance to bending stress or impact as the pipe itself. Certainly, the pipe or fitting should be checked for further structural damage, but once determined the affected area is only the cement lining, repairs can be made under the applicable provisions within the ANSI/AWWA C104/A21.4 standard CEMENT-MORTAR LINING FOR DUCTILE IRON PIPE AND FITTINGS.

-

McWane Ductile Participates in Career Development with Palm Beach County Water Utilities

07/27/2018 In ServicesOn July 24, 2018 the ½ Day of Water event took place at the state-of-the-art training facility in West Palm Beach Florida. The utility’s sprawling and beautiful center has significant space for hands-on training, large dual-screen high-resolution digital presentations, individual and group computer skills and software training, and so much more. Nearly 40 Palm Beach County utility workers, ranging from field personnel to design engineers, plant operators, and department managers were in attendance.

-

Ductile Iron Pipe Markings: What Do They Mean?

07/24/2018 In ProductsAll ductile iron pipe manufacturers use markings in a similar manner to assist customers in selecting the right material for the project. This includes verifying the material is suitable for the application intended (i.e. water or sewer) as well as adhering to the project requirements as stipulated by the owner/engineer for pipe class, lining, and exterior coating.

Because the colors used by each manufacturer may vary, we will explain how McWane Ductile applies these markings and describe their need and locations.

-

ACE'18 Pipe Tapping Contest

07/20/2018 In TechnicalMany of you may have had the opportunity to attend the AWWA/ACE 18 Conference held in Las Vegas just a few weeks ago. Among the many highlights of that show is the Annual Pipe Tapping Contest.

The participants consist of both US and International teams that are selected through a qualifying process where they would have competed in various regional or sectional events held throughout the preceding year.

-

How Do Spigot Stripes Assist in the Assembly of Ductile Iron Pipe?

06/22/2018 In InstallationSpigot stripes are used as a guide for assembly and a deflection check after assembly. Pipelines are not always designed in a straight line. It is often necessary to deflect pipe from a straight line to follow the curvature of streets and roads both vertically and horizontally. Ductile iron pipe is well suited for joint deflection.

-

What is TR Flex® Pipe and How is it Assembled?

06/08/2018 In InstallationTR Flex® is the most-widely accepted and installed integrally-cast restraint joint system in the ductile iron pipe industry. Proven as a versatile and easy-to-use item, this joint is flexible, sure, and watertight to and beyond it’s up-to-350-psi pressure rating while preventing longitudinal separation of the joints whether installed above or below ground.

-

8 Reasons to Choose McWane Ductile For Your Ductile Pipe Needs

06/01/2018 In Our CompanyHaving managed water and wastewater systems for most of my career, I have engaged with interest in the operations of specific water systems. Many times, those conversations have lead into areas beyond the engineering criteria for daily operations and into areas such as customer satisfaction. The great majority of these systems meet all required regulatory quality standards each day. Then why do customers become dissatisfied with the utility? One notable answer: SERVICE.

-

How Many Restrained Joints Do I Need When Designing a Project?

05/31/2018 In InstallationRestrained joint systems are used because standard slip joint (Tyton®) pipe does not provide significant restraint against separation of the joint created by unbalanced thrust forces. It could take as little as 30 to 50 psi to separate a Tyton® joint.

These forces are typically caused by changes in direction such as bends, tees, dead ends, valves, etc. in the pipeline.

-

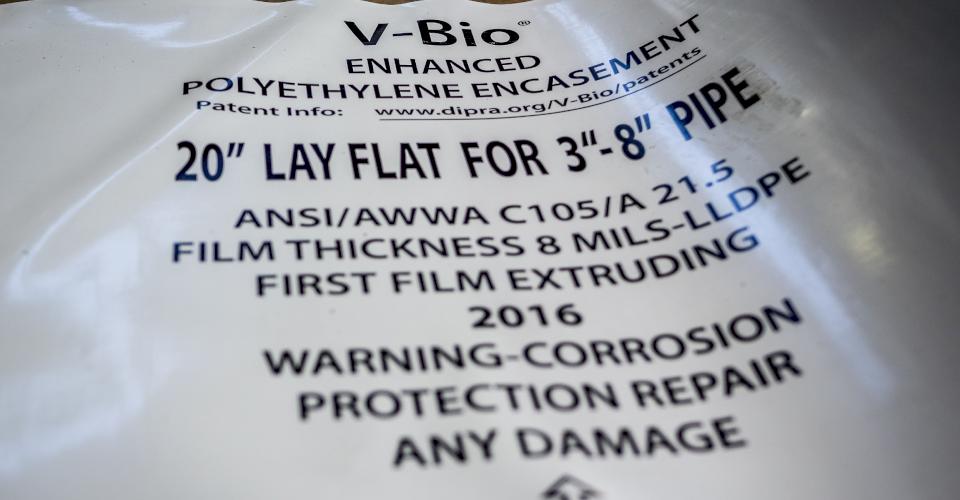

Eight Steps for Installing V-Bio® Polywrap (With Video)

04/06/2018 In InstallationPolyethylene encasement (polywrap) has been used since 1958 to protect ductile iron pipe from corrosion. It is the most popular, economical, and successful method for protecting pipe from corrosion.

A new advancement in polyethylene encasement called V-Bio® adds additional protection by inhibiting the formation of corrosion cells under the wrap. McWane Ductile added V-Bio® polywrap to its line of products in 2015. Adding a few steps to your pipe installation with V-Bio® is an Iron Strong decision that will benefit your pipeline for generations.

Latest Posts

- The Iowa Treated Water Pipeline Project: Providing Growth with Safe, Clean Water 11/09/2021 In Installation Services

- Hydrotesting on Slopes: The Hills Have PSI! 10/28/2021 In Installation Technical

- Barrel Rating vs. Joint Rating for Ductile Iron Pipe: Is There a Difference? 10/15/2021 In Technical

- Corrosion Control - Inside and Out - for Ductile Iron Pipe 10/08/2021 In Products Technical